Biomethane

One single partner for biomethane metering and analysis

Biomethane enters the grid only when it is safe, compliant and fully accounted for.

Regas designs and manufactures feed-in stations that integrate fiscal flow and energy measurement, continuous gas quality analysis, pressure regulation, and odorization into a single system.

Regas Biomethane Stations are all-in-one and tailor-made solutions designed for direct feed-in, tanker loading, liquefaction systems, and automotive methane.

- Tailor-made biomethane cabins assembled on skid

- Integrated fiscal measurement and gas quality analysis

- Compliance with technical and metrological regulations

- Solutions for network input, virtual pipeline and reverse flow

Regas know-how in Biomethane

- FIeld Experience

More than 70 biomethane plants served in agricultural and livestock, FORSU and agro-industrial settings, with varying operational and regulatory requirements. - Know-how in gas measurement

We have been involved in natural gas measurement since 1998: this expertise is now applied to renewable gases, with the same precision and reliability.

Digitalization and remote control

Telecontrol, data historization and diagnostic support enable continuous and proactive monitoring of gas quality, measurement and plant status.Service and Support

A network of trained technicians ensures startup, scheduled maintenance and prompt service, minimizing unplanned downtime.

Regulatory Compliance

Plants designed according to UNI/TS 11537:2024, UNI 11885:2022 and grid operator requirements, to reduce the risk of non-compliance and simplify the connection process.Modular and scalable solutions

Skids and modules that can be configured according to flow rates, site layouts and plant growth phases-from the first pilot configuration to more complex plants.

Case Study

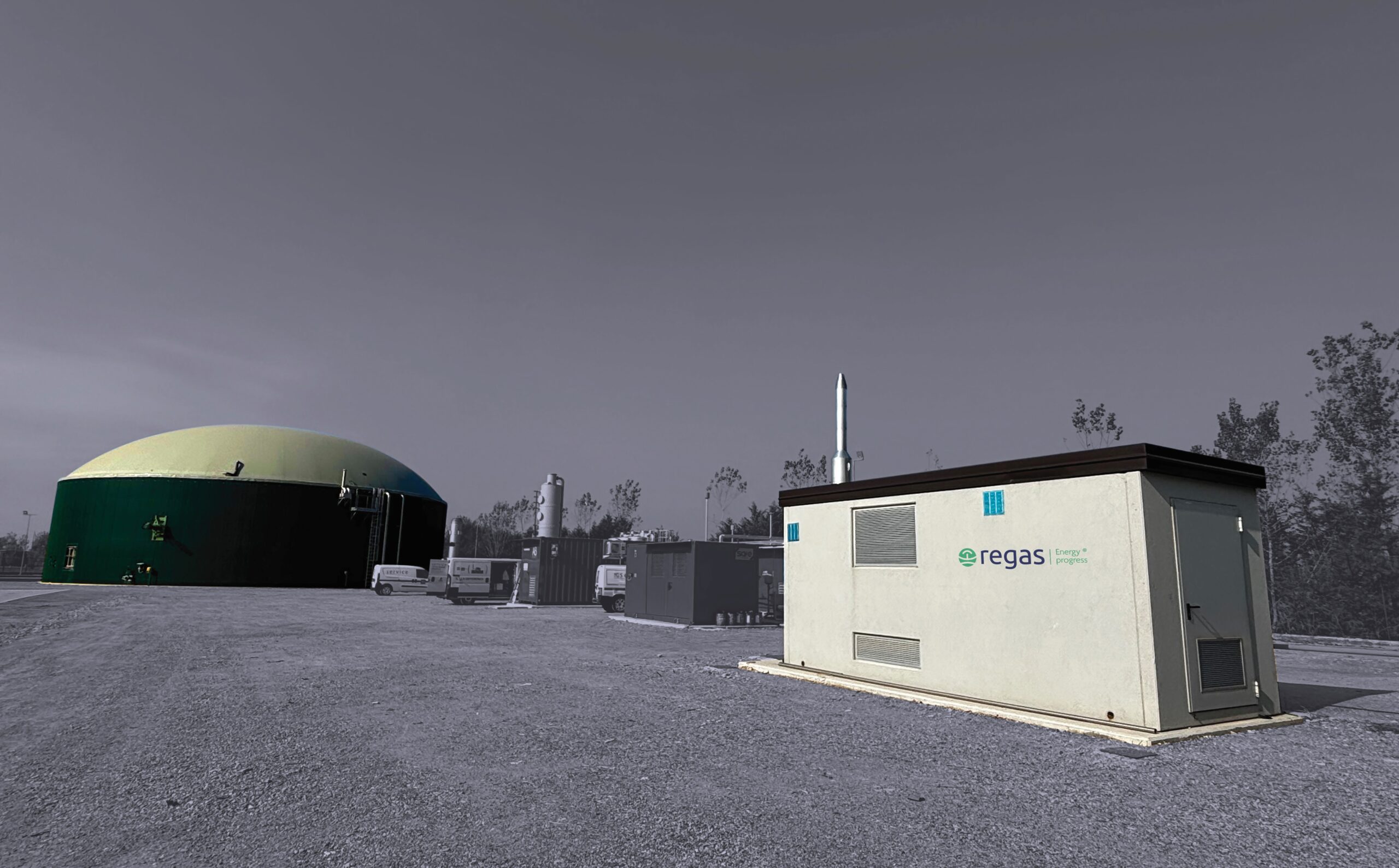

Biomethane cabin for biogas upgrading plant, Caravaggio (BG)

Bizzoni’s farm in Caravaggio (BG) chose to enhance wastewater and by-products through an anaerobic digestion plant with biomethane upgrading intended for feeding into the gas grid. The goal was to maximize hours of operation and minimize downtime due to gas quality and metering problems.

Ensure full compliance with quality specifications for feed-in

Respond to network operator requests in terms of traceable and easily verifiable fiscal measurement

Adapt the booth to the specific plant and logistic needs of the customer

Ensure timely service to minimize the risk of plant downtime

Regas provided a turnkey biomethane delivery and measurement plant consisting of:

- In-line analysis system for continuous monitoring of composition, calorific value and Wobbe index

Fiscal measurement skid of energy fed into the grid, complying with the operator’s requirements

Control and safety systems integrated with the rest of the system

Remote monitoring and data acquisition for remote monitoring and reporting to the network operator

Reverse Flow

Advanced solutions to inject gas back into the transmission network

In many local grids, the growth of biomethane production can lead to saturation situations: the distribution network can no longer absorb all available renewable energy and production is penalized.

Reverse Flow solutions allow gas to be transferred from the distribution network to the transportation network, freeing up capacity, keeping plants running and fully valuing the biomethane produced.

In this field, Regas designs tailor-made RE.MI. cabins that integrate deodorisation, compression, cooling, gas analysis and measurement, in collaboration with network operators and specialised technology partners.

Case Study

Reverse Flow Plant, Avetrana (TA)

At the IPRM site in Avetrana (TA), Italgas has built one of the first reverse flow plants in Italy, as part of the pilot projects incentivized by ARERA Resolution 404/2022/R/gas.

The objective was to find a concrete solution to the problem of saturated local distribution networks, which prevent renewable gas production from being fully exploited and limit the overall flexibility of the gas system.

The plant operates over an indicative pressure range from about 3 bar up to 70 bar,

allowing gas to be transferred from the distribution network to the transportation network safely and in compliance with the technical requirements of the system.

- Allow gas to be fed from the distribution network (low/medium pressures) into the transmission network.

- Increase the resilience and flexibility of the gas infrastructure in an area with a strong presence of local production.

- Demonstrate a replicable solution on a national scale, within a regulated and experimental regulatory framework.

- Integrare la soluzione Integrate the solution with technologies that are also ready for future hydrogen-mixing scenarios (H₂-ready).

Regas designed and supplied a tailor-made RE.MI. booth with integrated functions of:

Deodorization of gas before compression,

Cooling,

Gas quality analysis,

Integrated measurement and management for delivery to the national transportation network.