H2

The energy of the future

Hydrogen is the most abundant element in the entire universe. It makes up 90% of the Sun and on Earth it represents 75% of the matter around us, being present in a variety of elements, from water to organic compounds such as hydrocarbons.

The hydrogen molecule tends to bind to other atoms and therefore it is difficult to find it in nature in its pure state. Pure hydrogen is an extremely interesting energy vector: it is a fuel with a high calorific value and burns without emitting CO2. This is why it is the ideal candidate for the future zero-emission conversion of numerous energy-dense processes.

The “greenest” hydrogen

Today, hydrogen is mainly used in the oil and gas sector as a chemical reagent in oil refining processes. More than 95% of global production comes from steam reforming of fossil methane, a process that is efficient on a large scale but highly emissive, with a ratio of 9 kg CO2 for every kg H2 produced, known as grey hydrogen. When combined with CO2 capture and storage technologies, this results in blue hydrogen, which reduces emissions but requires the management and storage of large quantities of CO2.

Green hydrogen, on the other hand, is produced by electrolysis of water using electricity from renewable sources, without CO2 emissions, and is crucial for decarbonisation. This form of hydrogen can be produced on different scales, anywhere, and by anyone, using only water. It currently accounts for less than 5% of global production, but is expected to increase significantly due to falling renewable energy costs, technological advances in electrolysis cells, and the expected increase in CO2 costs

With 1 kg of green hydrogen you can:

source: www.snam.it

Move a fuel cell car

for 130 km

Heating a house

for 2 days

Produce steam

for 42 kg

Produce steel

9kg of steel from raw iron

Reduce CO2 emissions

If mixed with 62kg methane

Reduce CO2 emissions

If used in industry as a substitute for H2 Grey of 9Kg

Reduce CO2 emissions

If used for 15Kg automotives

Why choose Regas?

- 100% Italian production

- Plug & Play systems easily transportable and installable

- Highly customizable systems, designed to meet any production demand

- Qualified staff for pre and after-sales assistance and widely present in the national territory

- Customised turnkeys solutions for any size

- System that communicates with devices for the control and tracking of Hydrogen in the infrastructure

- High level control able to centrally coordinate production and consumption

Countless applications

Its applications are manifold

Given the possibility of being injected and transported in the current network of methane grid, it can be used in a mixture or in replacement of natural gas to provide thermal energy to all users: from domestic heating to large hard-to-abate production processes. For this reason it has emerged as a pillar of international energy strategies assuming a key role in guaranteeing European and international targets towards decarbonisation.

It can also be converted back into clean electric energy using of fuel cells acting as a vector with enormous potential in terms of non-programmable renewable energy storage.

Finally, it can be used in chemical reactions such as methanation to produce synthetic hydrocarbons.

Innovative Technologies

Regas, innovative technologies at the heart of the hydrogen supply chain.

Regas is an energy company with innovative DNA, environmental awereness and a 25-year success story. Since the foundation Regas has stood out for its concrete commitment to the topics of environmental sustainability and a growing interest in the energies of tomorrow.

We study, design and test solutions to integrate hydrogen in the world of natural gas, both for energy distribution and for the industrial and civil sectors, as we believe it can be a valuable ally in achieving international decarbonisation objectives.

In 2020, Regas joined the European Clean Hydrogen Alliance together with the major global players in the energy sector in order to jointly launch research projects to achieve European climate neutrality.

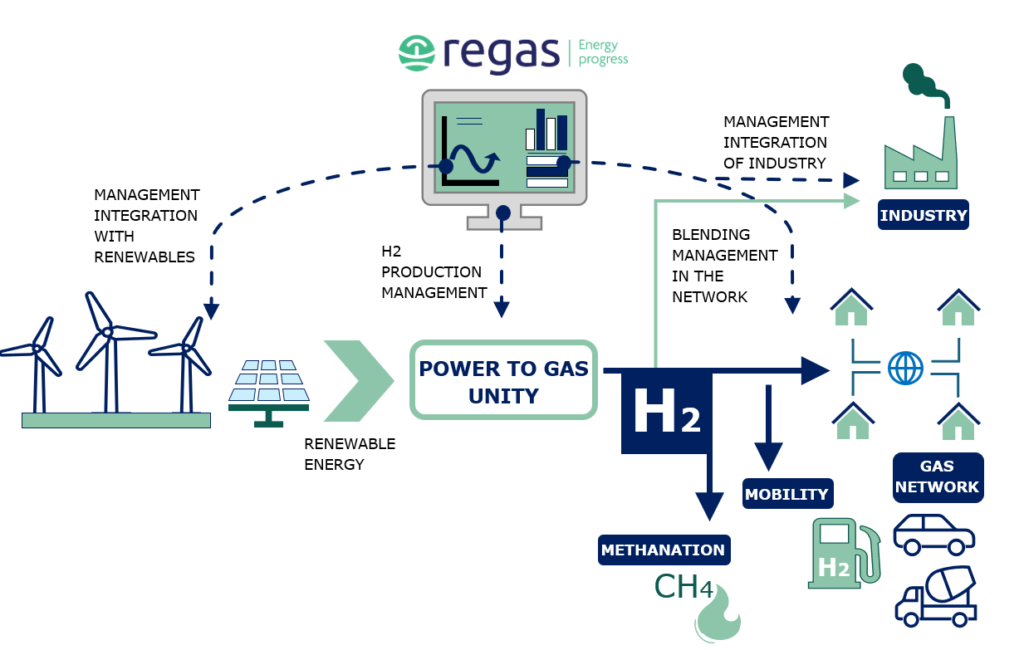

Power-To-Gas

Advanced power-to-gas systems for any hydrogen application.

Our Power-To-Gas solutions

In early 2021 Regas signed an agreement with ErreDue S.p.A, the largest Italian manufacturer of electrolysers with twenty years of experience in developing electrochemical technologies for the production of technical gases on-site. This strategic partnership combines the quality assurance of key technology with Regas’ ability to integrate it into all energy sectors through automated and IoT solutions.

The system offered is easy to transport and install and is totally customizable. The size and storage can be modulated according to the customer’s needs and guarantees a controlled and customizable mixing on the Hydrogen standard according to the need.

Who are our Power-to-Gas solutions developed for?

Natural gas transporters and distributors

We offer them technologies and devices to manage the production and mixing of hydrogen in the gas grid, integrating it with the electricity grid or directly with production from renewables. We also monitor the flow and use of green hydrogen along the grid, up to the end users.

Renewable energy companies

We offer them the possibility of using green hydrogen as a high energy density vector for storing the production surplus. This allows them to transform the problem of non-programmability of production into a double benefit: on the one hand the production of a value energy vector and on the other the possibility to offer programmability and flexibility to their own plant.

Industries operating in the Hard-to-Abate sectors

These are steel, cement, glass, ceramic, paper and aluminium industries with facilities to produce in-house hydrogen for use as fuel in their production processes at high temperatures.

Research

Hydrogen production systems are very useful and required within the most varied research projects that aim to study new uses and applications of the molecule.

Ports and Airports

Aviation and shipping consider the use of green hydrogen, in purity or as a material to produce synthetic hydrocarbons, as an excellent solution to reduce the emissions caused by the use of fuels, essential in these sectors. In addition, the large spaces available are suitable for the installation of photovoltaic to reduce hydrogen production costs.

For a 4.0 gas grid

DIGITAL, SMART and HYDROGEN READY.

In addition to the best and most reliable Power-to-Gas technology, which transforms the electric surplus into hydrogen and makes it transportable from the current distribution infrastructure, we provide a complete range of products and services to adapt the network to the new scenario.

Our products are designed to satisfy the needs arising from new flows in the network, such as the new odorization requirements, the different pressure management and the need for constant and reliable monitoring of variable mixtures at various points in the grid.

Regas products are highly customizable according to the needs of each distributor, range from high-precision hydrogen injection systems, gas chromatographs able to remotely analyse every component in the network, up to an advanced digital solution capable of tracing, analysing and predicting network behaviour making it fully digitized and SMART.

RegaSphere is our digital platform able to remotely manage and monitor the entire gas infrastructure, which becomes more complex every day, in an easy, timely, intuitive and extremely safe way.