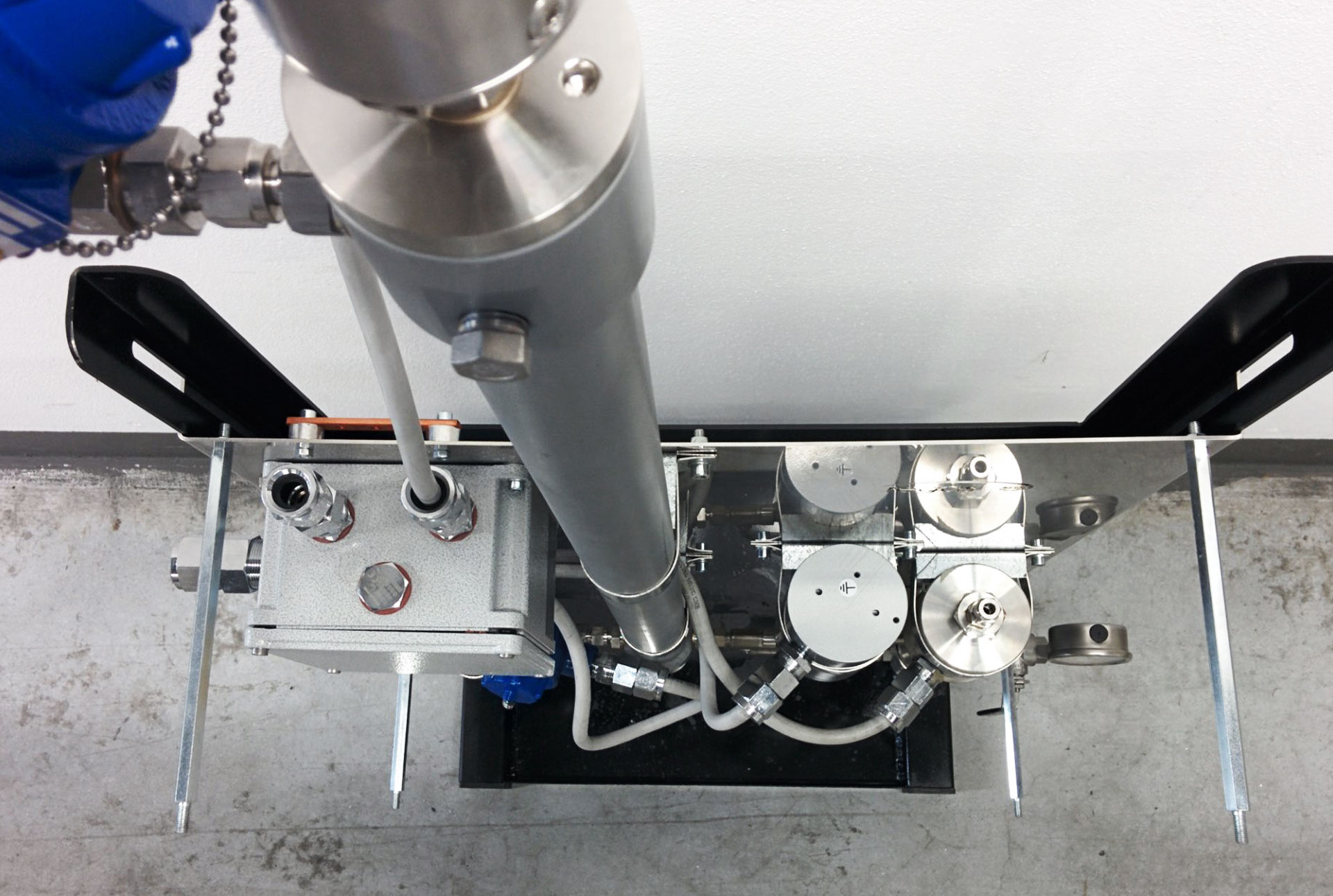

Ingrid 1 - Automatic odorant injection system

-

Built-in Electronic Level

-

Compact and Universal Support System

-

High Efficiency Pressure Generator

-

Double Active Odorant Filtration

-

Standardization of sizes

The system integrates an electronic magneto-strictive level that measures the residual amount of odorizing liquid in the tank and verifies the exact amount fed into the grid.

This ensures perfect odorant load balancing and accurate control of the amount of odorant.

The standard level is 800 mm, a quantity that allows immediate adaptability to a variety of plants.

The support frame is characterized by limited volume and can be easily installed both on the floor or wall.

This allows INGRID to be installed even in small spaces and in difficult environments.

The support system, adjustable in height, allows immediate adaptability to a variety of plants.

The motor-pump block has extremely low electricity consumption and its mechanical design eliminates the possibility of any malfunction. This guarantees the perfect functionality of the system in a variety of contexts and with power supply even by photovoltaic plants.

Odorant filtration system both at the inlet and outlet of the system.

An innovation that doubles the filtering surface and simplifies maintenance.

This maintains a high purity of the product input, ensuring the efficiency of the entire system over time.

The level and the components in general have been unified, thus ensuring the applicability of the system to various sizes of tanks and to numerous types of plants.

This allows a total interchangeability of the components and the general efficiency in the management of the machinery.

Strengths

- Direct injection odorization system able to guarantee the correct odorization ratio for each cubic meter of natural gas supplied

- Built-in remote control system

- Maximum compatibility with third-party SCADA systems

- Built-in and high definition electronic magneto strictive level indicator

- Remote and local odorization ratio regulation

- Can be combined with any type of tank

- Solid and compact design

- Available in a self-powered version for installation not reached by the power grid

- Available in a version for high-pressure networks

- Backup system and automatic transition to bypass odorization

Ingrid 2 - Automatic system of odorant injection

The renewed layout ensures the operation of INGRID 2 even in non-standard plants, allowing the installation with any type of withdrawal tank. The new integrated pressure generator ensures continuous operation. The innovative and exclusive solenoid valve, available as an option, represents the highest level of guarantee of mechanical odorization in case of any machine downtime.

Equipped with advanced sensors, INGRID 2 allows you to identify the causes of most malfunctions remotely, making after-sales technical support more efficient and rapid.

INGRID 2 already communicates with third-party SCADA allowing customers to monitor and control it remotely using their own specific control systems. This possible configuration, available as an option, is designed to meet the specific needs of each customer thanks to the software and PLC expertise within the Regas staff. If the customer is not equipped with SCADA, the RegasSphere platform is available as a subscription, entirely in the cloud and based on the highest standards of cyber-security, which ensures remote control and command of all major Regas field systems through a common web browser.

There are already numerous distribution networks in which the concentration of odorant is managed independently and dynamically thanks to the patented application ROSE. Thanks to an optional module, part of the RegasSphere system and in combination with the compact REGAS field GCs, the concentration of the odorant is continuously varied according to the instantaneous conditions of the network so as to ensure a level of odorization always conforming to the network, ensuring the lowest consumption of odorant at the injection point.

As with previous product lines, REGAS develops specific projects where process conditions become specific and particularly serious. REGAS has already developed several injection systems for odorant specifically for:

- High capacity systems, even over 500,000 stmc/h.

- CNG systems at very high pressure.

- Very low capacity stations, such as remote REMI, micro-LNG and channelled LPG.

Advantages

- Robust and compact design;

- Automatic adjustment of the odorization rate with high degree of accuracy through the use of an injector;

- Continuous control of the quantity of the injected odorant;

- Measurement of the residual amount in the odorant tank in millimetres, litres and percent;

- Possibility to remotely acquire and control many operating parameters;

- Remote access to the operator panel to view status and change parameters;

- Compatibility with proprietary or third-party SCADA;

- UPS options available;

- Backup system available and automatic switch to bypass mode;

- Possible variants (Ingrid HP, Low Emission).

-

High Efficiency Pressure Generator

-

Built-in Electronic Level

-

Compact and Universal Support System

-

Double Active Odorant Filtration

-

Standardization of sizes

Advanced sensors, integration of sensors that improve the diagnostics of any malfunctions minimizing the possibility of downtime.

The motor-pump block boasts extremely low electrical consumption and its mechanical design cancels the possibility of any malfunction.

This guarantees the perfect functionality of the system in various plant contexts and with power also from photovoltaic systems.

The system integrates a magneto strictive electronic level that measures the residual amount of odorizing liquid in the tank and verifies the exact amount fed into the network.

This ensures perfect planning of odorant loads and accurate control of the amount of product fed into the network.

The standard level is 800 mm, a measure that allows immediate adaptability to various types of plant.

The support frame is characterized by small dimensions and can be installed both on the floor and on the wall with extreme simplicity.

This allows the installation of INGRID even in small spaces and in harsh environments.

The support system, adjustable in height, allows immediate adaptability to various types of plant.

Odorant filtration system both in and out of the system. An innovation that doubles the filtering surface and simplifies maintenance.

This maintains a high purity of the input product ensuring the efficiency of the entire system over time.

The level and the components have generally been unified thus ensuring the applicability of the system to various sizes of tanks and numerous types of plant.

This allows a total interchangeability of the components and the overall efficiency in the management of the machinery.

Regas embraces change and moves

by listening to the needs of a world

in continuous transformation.

LOGISTICS HUB

SOUTH OF ITALY

LOGISTICS HUB

FRANCE

Membro di