Emma- Patented natural gas preheating system

The right amount of energy per cubic meter of gas

Patent EP2715213

REGAS constantly invests in research and development to give technologically advanced answers to the needs of its customers.

This is the case of EMMA – Energy Multi-variable Master – the real-time control unit that allows to achieve the best performance during the preheating phase, reducing gas self-consumption and CO2 emissions

- Easy to use

- Reduction in natural gas consumption: 36% on average

- Reduction of CO2 emissions: allows to obtain energy efficiency certificates

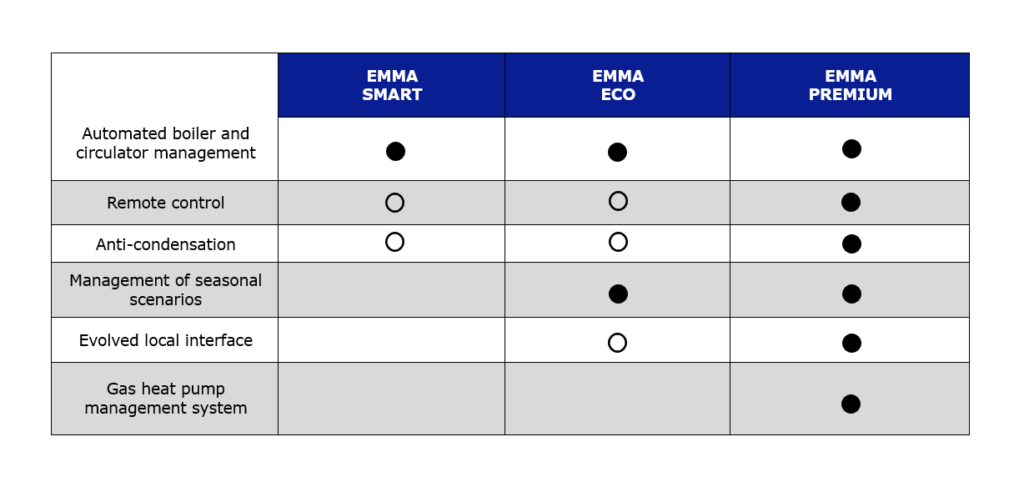

- Available in 3 versions: SMART, ECO and PREMIUM

- Compatible with third party management systems

- Applicable to existing stations without plant modifications

- EMMA Premium: in combination with GAHP technology allows up to 50% more efficiency than standard preheating systems

How EMMA can help the gas industry save and reduce CO2 emissions

Emma Eco

Remote control version for the centralization of decisions and the possibility to operate with significant time and operation savings. Through the integrated network interface, the system provides the user with all configuration parameters, status control and parameter logging.

Version for remote control. Through the integrated network interface, the system provides the user with all configuration parameters, status control and recording of parameters such as water and gas temperature and station flow rate. The remote control allows the centralization of decisions and the possibility to operate on plants without the need to be present on site, with significant savings in terms of time and operation, as well as tangible benefits for operational safety.

Based on user-specific settings, you can set alarm alerts based on each detected state. This information is transmitted to the remote control software (both in the case of CCR - software owned by REGAS - and third-party SCADA) and appropriately stored.

Data: The values from the process are continuously recorded and can be analysed by the software, even in offline mode.

Inputs: The system allows remote input commands.

Emma Premium

The already high efficiency offered by EMMA ECO can be increased thanks to the use of renewable energy. REGAS has managed to combine new technologies with traditional systems, thanks to the gas absorption heat pump (GAHP), able to achieve significant savings performance. Through a minimally invasive installation, which maintains the accessibility and safety of the existing hydraulic circuit, EMMA PREMIUM achieves efficiency performance, never seen before, in terms of gas consumption and respect for the environment.

The GAHP heat pump is installed in parallel with traditional boilers, and the inlet and outlet pipes derive from the existing ones.

Reduction in natural gas consumption (on average -36%)

Reduction of CO2 emissions: allows obtaining TEE (energy efficiency certificates)

Compatible with third-party remote management systems

Applicable to existing stations (retrofitting)

Emma Premium: in combination with GAHP technology allows up to 50% more efficiency than standard heating systems

Self-learning algorithm for maximum performance

Turn-keys

The high specialization of REGAS allows to provide EMMA PREMIUM with the turnkey formula.

Emma Premium

A perfect example of integration between renewable energy and technology at the service of the gas industry, in compliance with the emission reduction goals dictated by Italian and transnational regulatory authorities.